IMS designs, manufactures and implements standard or customised omnidirectional, turnkey air-cushioned handling systems on site.

Bertin technology

Easier load positioning thanks to air cushions

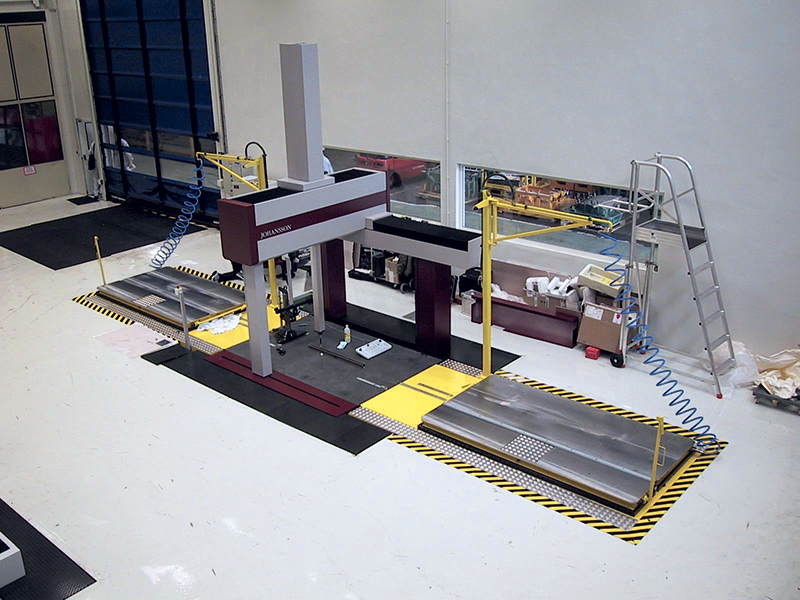

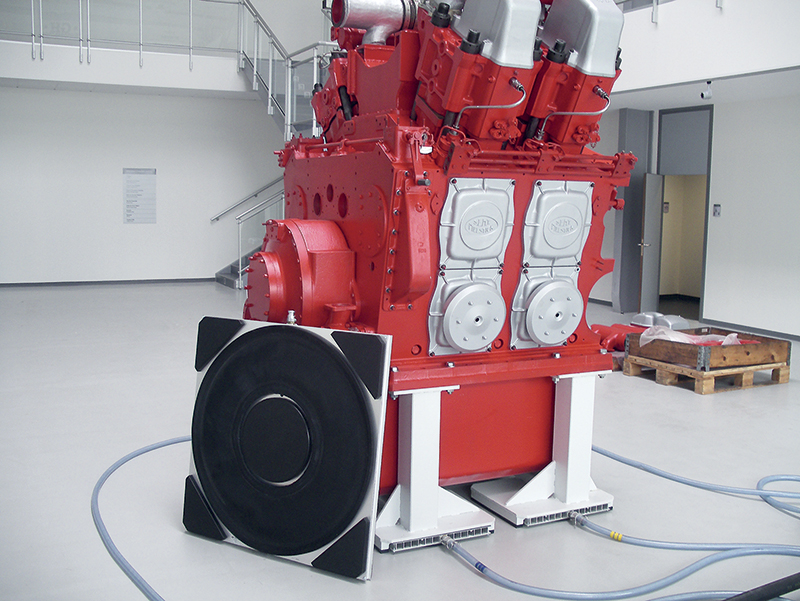

Air cushion modules may be fitted to existing structures for transport purposes; in the case of exceptional handling operations, they may be placed directly under the load.

Pressure in the air cushion modules is increased until they lift the load and an air film is established between them and the floor surface; for this process to succeed, surface must be smooth and watertight. (Click here to see surface specifications.)

The load thus floats on a film of air, with almost no friction; as a consequence, it is easy to move and position heavy loads with very little effort, and in whatever direction.

On-site air-cushioned handling performed by IMS team

STANDARD RANGE

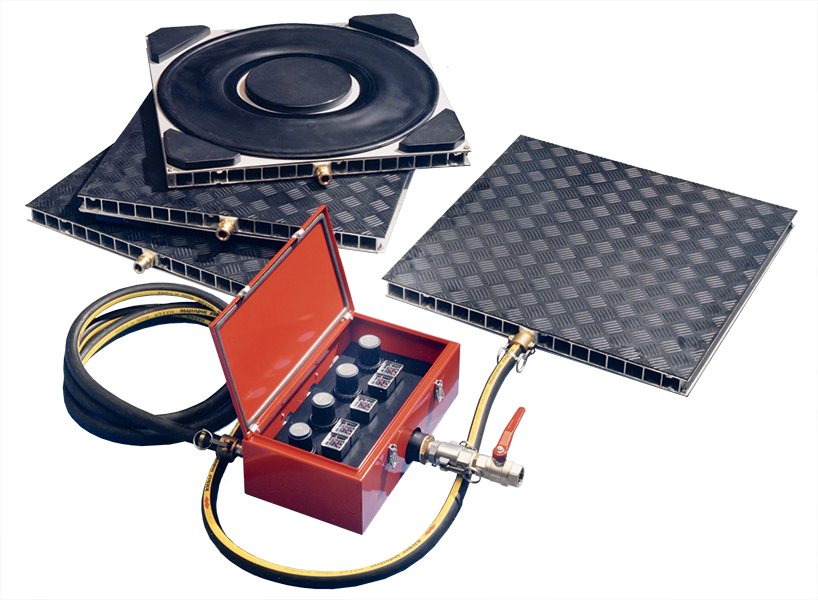

MODULAR KIT FOR PLACEMENT INTO EXISTING STRUCTURE

At least three modules are required to ensure stability. Each module is connected to a control box, itself connected to the air source. Regulators are then opened one by one until the load floats (eccentric loads require individual adjustments).

Regulation (manual or automatic) is used to individually adjust the air cushion modules and balance load distribution until the load floats with very little effort.

Pressure in the air cushion modules is increased until they lift the load and an air film is established between the modules and the surface, which must be watertight and smooth. The load floats on an air film, with almost no friction; this makes it easy to accurately move and position HEAVY and/or FRAGILE loads in whatever direction.

BESPOKE SOLUTIONS

WE DESIGN EQUIPMENT PER YOUR SPECIFICATIONS

IMS designs turnkey, compact, radio-controlled, agile, quiet and environmentally friendly pneumatic technology air-cushioned handling equipment, pursuant to EC regulations.

This air-cushioned equipment is designed for handling heavy, atypical loads, such as sub-assemblies and special machinery, railway equipment, civil engineering structures, sensitive and fragile loads, aeronautical and space engines and structures, or items from the nuclear and military industries etc. Indeed, our air-cushioned solutions offers manufacturers a convenient tool for the regular transport of special, non-standard loads.

Our air-cushioned equipment has multiple applications in all industrial sectors.

BESPOKE SOLUTIONS

AIR-CUSHIONED HEAVY LOAD TURNTABLE

Use of air cushions in the production of large-scale turntables for heavy loads, with manual or powered rotation.

TECHNICAL SPECIFICATIONS:

- Effortless radio-controlled (or manual) load displacement, ensures perfect control

- Excellent omnidirectional manoeuvrability, ideal for tight spaces

- Flexibility of use, very easy to implement by non-specialised staff

- Loads are moved safely, without vibrations

- Loads deposited carefully, without any surface deterioration

- Flame-proof equipment

AIR CUSHION OPERATION:

- Reinforced coated canvas circular toric skirt inflates as it fills with air.

- As the air pressure increases, the module lifts off the ground.

- When pressure in the skirt is greater than load counter-pressure, air escapes between the skirt and the floor, forming a thin air film on which the load floats virtually frictionlessly.

Ground surface is key to a successful operation:

Ground surface quality is important for implementation of air-cushioned handling technology and to optimise equipment air consumption.

In addition, surface quality is also decisive in reducing the force required to displace loads.

Optimal operation requires a smooth, watertight floor surface (float-finished glazed concrete floor, self-smoothing epoxy resin, etc.).

Lastly, for exceptional handling needs, any surface imperfections may be covered with thin sheets, plates or rolls of sealed PVC or polyester, etc. (Click here to see surface specifications.)

ADVANTAGES OF AIR-CUSHIONED SYSTEMS:

Modular or turnkey air-cushioned systems are designed for handling heavy loads, such as machine tools, bridge decks, and sensitive, high-added-value loads, etc.

They allow for effortless, omnidirectional load displacement.

Compact, space-saving, quiet, non-polluting and almost maintenance-free.

Our air-cushioned equipment has multiple applications in all industrial sectors.